- The gray electrical tape's primary purpose is electrical insulation. It provides a reliable barrier between wires and the elements, protecting against short circuits and electrical fires. Its durability ensures that it can withstand a range of temperatures without degrading, making it suitable for both indoor and outdoor applications. Electricians and hobbyists alike trust this tape for its consistent performance and ability to adhere securely to a variety of surfaces, including plastic, metal, and rubber.

- Furthermore, foil-backed butyl tape is also highly resistant to chemicals and solvents, making it an ideal solution for applications where the tape may come into contact with harsh chemicals or solvents. This makes it an excellent choice for sealing pipes and tanks in chemical processing plants, refineries, and other industrial environments.

- Edge sealants are used for thin film and crystalline silicon PV modules. It helps in delaying moisture ingress, which protects cells, connections, and conductive oxide coatings from corrosion and degradation. Edge sealants also strengthen the electrical isolation for PV modules. The many advances in sealing systems help PV manufacturers in finding ways to reduce costs and improve the protections of cells. Sealants have many forms which can be used, including liquid and tape forms. Edge sealants are required to provide the following properties to the solar PV modules:

- The term butyl refers to the primary adhesive component, a synthetic rubber known for its excellent sealing and bonding properties. It is renowned for its flexibility, conformability, and ability to adhere to a wide range of surfaces, including wet and uneven ones. On the other hand, the foil component, typically aluminum or copper, provides the tape with its durability, heat resistance, and barrier properties against water, air, and UV radiation.

Red - In conclusion, floor safety strips are an essential safety feature in any building or facility. By installing safety strips on slippery or wet surfaces, the risk of slips and falls can be greatly reduced, protecting employees, visitors, and customers from potential injuries. With their easy installation and minimal maintenance requirements, safety strips are a simple and cost-effective solution for improving safety and preventing accidents. Investing in floor safety strips is a smart choice for any business or organization looking to create a safe and secure environment for everyone.

- Butyl rubber waterproof tape, an innovative solution in the realm of sealing and waterproofing, has gained significant recognition due to its exceptional performance and versatility. This specialized tape, derived from a blend of isobutylene and isoprene polymers, offers a robust and reliable means of creating airtight and watertight seals across a wide range of applications.

- Consumers have also seen benefits with self-vulcanizing adhesives and sealants becoming more common in DIY products

- In conclusion, yellow green insulation tape is more than just a simple adhesive strip; it is a critical component of electrical safety measures. Its distinctive color acts as a visual safeguard, reducing the risk of accidents and promoting compliance with industry standards. As technology continues to evolve, the importance of such safety-oriented tools only increases, underlining the significance of yellow green insulation tape in our daily lives.

purple pvc tape. Coaches often use it to mark training areas, create temporary boundaries, or even customize athletic gear. Its vibrant shade ensures that these markings stand out, enhancing the overall experience for players and spectators alike.

purple pvc tape. Coaches often use it to mark training areas, create temporary boundaries, or even customize athletic gear. Its vibrant shade ensures that these markings stand out, enhancing the overall experience for players and spectators alike.

5. Test the Seal Once applied, check to see if the seal is tight. You can do this by attempting to slide a piece of paper between the door or window and the frame; if it doesn’t slide out easily, your installation was successful.

Silicone insulation tape has become an essential tool in various industries due to its remarkable properties and versatility. Unlike traditional insulating materials, silicone tape stands out for its excellent heat resistance, flexibility, and durability, making it an ideal choice for electrical insulation, automotive applications, and even household repairs.

Wait, it gets hotter.

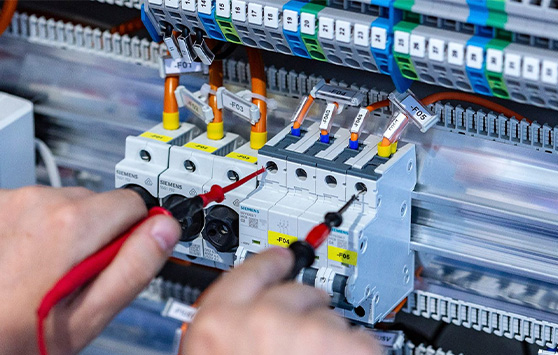

When you think of types of electrical tape, you probably imagine it in black. However, manufacturers produce electrical insulation tape in almost every color of the rainbow. The varying colors indicate voltage protection and insulation. It’s vital to use the right colored tape—an incorrect tape color puts technicians at risk of insufficient voltage shielding:

Whether sealing a leaky pipe or temporarily fixing a broken tool, black PVC tape can provide a quick and reliable solution until a more permanent fix can be made Whether sealing a leaky pipe or temporarily fixing a broken tool, black PVC tape can provide a quick and reliable solution until a more permanent fix can be made

Whether sealing a leaky pipe or temporarily fixing a broken tool, black PVC tape can provide a quick and reliable solution until a more permanent fix can be made Whether sealing a leaky pipe or temporarily fixing a broken tool, black PVC tape can provide a quick and reliable solution until a more permanent fix can be made black pvc tape.

black pvc tape.Prepare the Surface: Ensure the surface you're applying the tape to is clean and dry. This will help the tape adhere properly.

The Importance of Flame Retardant Tapes in Safety and Versatility